Your location:Home >Automotive News >

Time:2022-06-24 20:07:04Source:

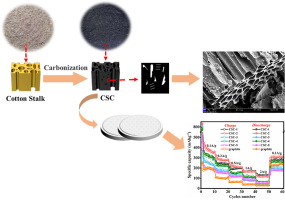

According to foreign media reports, researchers from Shihezi University in China explored the effect of cotton straw particle size on the structure of biochar and the performance of lithium-ion battery anodes.

(Image source: Shihezi University)

Lithium-ion batteries have the advantages of high energy density, light weight, long service life, and no pollution, and are very popular in the field of energy storage.However, the graphite anode commonly used in such batteries has limited capacity and poor rate performance.To improve battery performance, researchers are working to develop next-generation carbon anode materials.

this study

In this study, researchers explored the use of cotton stalk biochar (CSC) as an anode material for lithium-ion batteries and investigated the effect of particle size on the structure and electrochemical properties of the derived carbon materials.

The team used a one-step carbonization method to prepare the samples.Using larger cotton stalk particles as raw material to prepare biochar can preserve the tubular structure of cotton stalk and help to form a pore structure.

The researchers used agricultural cotton stalk waste as a precursor to investigate the effect of particle size on the structural and electrochemical properties of carbonized products.High-performance cotton stalk porous charcoal is fabricated through a simple carbonization process.

Observation results

As the scanning speed increases, the capacitance distribution gradually expands.When the scanning speed is 1 mVs-1, the capacitance distribution reaches 47.57%.When the current density is 2 Ag-1, the reversible capacity of CSC anode reaches 57.62-130.33 mAhg-1, while the reversible capacity of graphite is only 30.8 mAhg-1.The initial specific capacities of CSC-1, 2, 3, 4, and 5 were 786.5, 872.1, 857.8, 749.85, and 646.1 mAhg-1, respectively, and dropped rapidly during the first discharge/charge operation.In high-resolution O1s, C=O, C-OH, COC, and OH appear four peaks at 530.9 eV, 531.8 eV, 532.6 eV, and 533.6 eV, respectively.

When the particle size of cotton stalk is less than 200 μm, the structural characteristics of pyrolytic carbon change significantly, especially the pore size is less than 4 nm.The particle size range of carbonized cotton stalk products is 100-200 and 450-2000 μm, the maximum interlayer spacing is 0.388 nm, and the pore volume is 0.285 cm3 g-1.At the same time, the pyrolytic carbon made of larger cotton stalk particles has a better tubular structure.

After 100 cycles at 0.1 Ag-1, the Li+ diffusion coefficient of cotton stalk biochar with a particle size of 450-2000 μm is the largest, which is 1.47x10-11 cm2 s-1, and the electrochemical performance is the best. Large, reaching 271.7 mAhg-1.

The 200 μm cotton stalk particle is an important transformation point in terms of the structural properties and chemical composition of biochar.The cotton stalk biochar with a diameter of 450-2000 μm showed the best electrochemical performance, and the specific capacity reached 271.7 mAhg-1 after 100 cycles of 0.1 Ag-1.Meanwhile, at a high current density of 2 Ag-1, the specific capacity is 115 mAhg-1.

in conclusion

Taken together, this study demonstrates that CSCs with tubular porous structure, large interlayer spacing, and high heteroatom doping can be used to store and transport lithium ions.During pyrolysis, the larger cotton stalk particles contribute to the formation of pore structures and retention of heteroatoms.By changing the particle size of cotton stalks, the structure of biochar can be effectively controlled, and this future carbon material preparation method has low energy consumption and is environmentally friendly.The particle size distribution of biomass precursors has a great influence on the electrochemical performance and structure of biochar.

The researchers believe that screening the precursor particle size is a promising strategy for improving electrochemical performance and also provides ideas for developing other energy storage devices.Because the amount of this precursor is abundant, and the related manufacturing process is simple and low in cost.

Statement: the article only represents the views of the original author and does not represent the position of this website; If there is infringement or violation, you can directly feed back to this website, and we will modify or delete it.

Preferredproduct

Picture and textrecommendation

2022-06-24 20:05:26

2022-06-24 20:05:03

Hot spotsranking

Wonderfularticles

2022-06-23 17:56:06

Popularrecommendations