Your location:Home >Automotive News >

Time:2022-06-30 13:16:24Source:

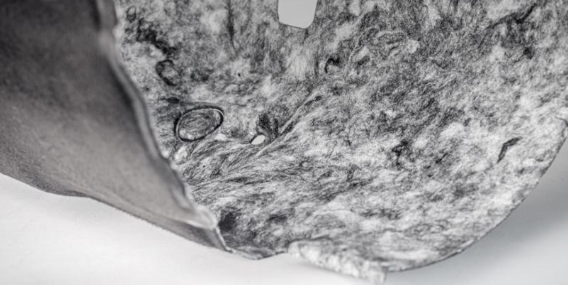

In order to meet the acoustic needs of electric vehicles, Autoneum has extended its proven noise-cancelling engine packaging concept to new applications related to electric drives, according to foreign media reports .Hybrid Acoustic PET and Foam-Based Alternatives Hybrid Acoustic FLEX and FIT FLEX can provide optimal noise protection for electric vehicles and significantly improve driving comfort.With high acoustic performance and no waste in the production process, these three technologies meet the specific needs of customers.

(Image source: Autoneum)

Interference noise creates new acoustic challenges for automakers around the world, such as high-frequency sounds from electric motors and other electronics, or noise from transmissions.Foreseeing the need for noise-reducing components in the front and rear of electric vehicles early on, Autoneum has extended its proven under-the-hood noise protection technology to new electric vehicle applications.

The company offers three standardized technologies, a hybrid acoustic PET with fiber technology and two foam alternatives hybrid acoustic FLEX and FIT FLEX, to reduce noise directly at the source, thereby improving driving comfort.Adjustable for different sizes and shapes, these three technologies are widely used in electric vehicles, such as motor packaging, as well as reducing noise and vibration in inverters, transmissions, pumps and compressors.By offering both fiber-based and foam-based materials, Autoneum has the flexibility to meet customers' individual needs and preferences in terms of materials, acoustic concepts, sustainability and cost.

In terms of sustainable noise protection in the engine compartment, the basic conditions of Opto’s patented innovative hybrid acoustic PET are: made of 100% PET, of which up to 50% of recycled fibers; scraps in production can be recovered, processed and reused, in At the end of the product life cycle, the material can be fully recycled.Part of the company's sustainable brand, Autoneum Pure, this unique textile technology is particularly well-suited to the fading high-frequency sound of electric drive units, and provides well-balanced absorption and insulation properties.In addition, components made of hybrid acoustic PET can reduce weight by up to 40% compared to standard insulators.

To meet the different needs of car manufacturers, Autoneum complements its lightweight textile technology with two foam-based alternatives.Both materials are infused with foam and are produced without waste.Hybrid Acoustic FLEX is based on the same acoustic concept as Hybrid Acoustic PET, but the separator is made of foam (instead of felt).On the other hand, Opto’s Fit FLEX combines a foam separator with an injection-molded thick layer.Because the foam is highly adaptable to the high geometry of complex shapes, both technologies provide excellent acoustic performance to isolate electric motors and other noise sources in electric vehicles.In addition, the absorbing or insulating acoustic qualities of the foam can be flexibly adjusted to meet specific customer needs.

Opto's innovative noise reduction technology can be used in electric vehicle motor packaging and other noise-generating components.Currently, it is available in the European, North American and Chinese markets.

Statement: the article only represents the views of the original author and does not represent the position of this website; If there is infringement or violation, you can directly feed back to this website, and we will modify or delete it.

Preferredproduct

Picture and textrecommendation

2022-06-30 13:16:24

2022-06-30 13:14:35

2022-06-30 13:13:55

Hot spotsranking

Wonderfularticles

2022-06-30 13:11:02

2022-06-30 13:10:00

2022-06-30 13:08:46

Popularrecommendations