Your location:Home >Automotive News >

Time:2022-06-02 12:01:10Source:

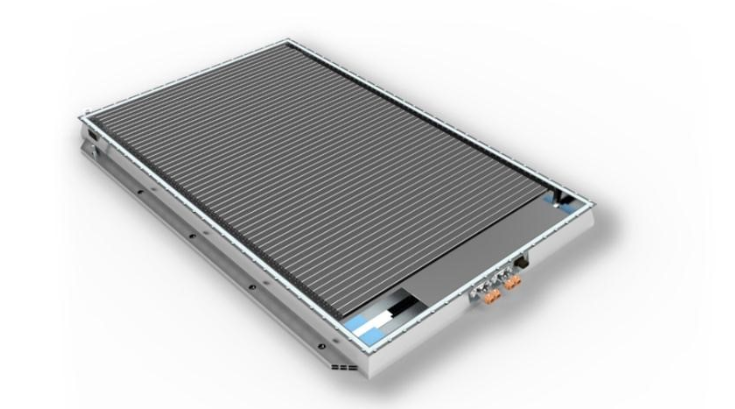

When it comes tonew energy vehicles, issues related to the safety, technology and quality of battery systems are always the most concerned.A few days ago, Nezha Auto officially announced and introduced its latest battery system, Tiangong Battery, to the media.Correspondingly, the biggest technical advantage of this product lies in the guarantee of extreme safety, significantly improved battery life and comprehensive service life.Specific to the technical design level: the first point is to create a super protection and highly integrated design, the second point is to create an efficient and intelligent constant temperature thermal management system, and the third point is to create a full life cycle battery closed-loop management system.

At this year's Shenzhen-Hong Kong-Macau Auto Show, the extended range version of Nezha S was officially unveiled, and with the launch of new Nezha S products, the official also introduced some technical specialties of its Shanhai platform. The Tiangong battery here is the key link. .Combined with the practical application of traditional battery systems and the pain points of users, Tiangong battery has been redesigned and calibrated in three aspects. First, the highly integrated design enables it to have betterlightweight, smaller size, and better efficiency. At the same time, it adopts fortress-type protection layer by layer to cut off all connections between thermal runaway and thermal runaway to ensure safety. In addition, it also has excellent durability.

For example, in terms of battery cells, Nezha Automobile has established more stringent battery cell application evaluation and selection specifications, including more than 900 battery cell selection evaluation requirements. Protective material, built-in short-circuit fuse protection, self-opening pressure relief explosion-proof valve and high-level pole insulation.In terms of modules, it adopts a mesh module design. The thermal insulation material between the cells is comparable to aerospace grade and can withstand high temperatures above 1000 degrees Celsius. At the same time, the electrical protection can also fully meet the 800V electrical insulation redundancy safety design. , The whole module is a lightweight and high-strength aluminum frame, which ensures structural safety and better weight reduction.In addition, the Pack also adopts a cabin-type box structure. Thanks to this, the safety of Tiangong batteries is protected to the greatest extent.

In terms of thermal management, Nezha Auto's self-developed HozonEPT 4.0 intelligent temperature control system is mainly aimed at the performance of battery life, energy consumption and low temperature status. According to the official data, after using this system, the winter battery life can be increased by 20%. , the energy saving of a single charge can be increased by 2%, and the low-temperature charging efficiency can be increased by 20%.Specific methods, such as the use of intelligent feed-forward thermal management control, can estimate cooling/heating needs according to working conditions, heat pump multi-heat sources can achieve driving heating and heat preservation, with advanced heating strategy, can be based on navigation destinations. hot.At the same time, the efficient cooling and heating system adopts a constant temperature liquid cooling strategy to better optimize energy consumption efficiency and improve battery life.Applied to the car, the CLTC battery life of the Nezha S two-wheel drive pure electric version can reach 715 kilometers, and the NEDC pure electric battery life of the extended-range version of the Nezha S can also reach 300 kilometers.

It is worth mentioning that the BMS ecosystem of people, cars, and clouds developed by Nezha Auto can realize the application of "Thousand Vehicles, Thousands of Policies".Algorithm capabilities covering all scenarios, including SOH, lithium precipitation, outliers, safety warning and other algorithms, covering multiple scenarios such as driving, charging, stationary, etc., can effectively identify thermal runaway problems at the first time.

According to reports, Nezha Tiangong battery is in the process of continuous change and development. It is mainly divided into three stages. In 2020, a standardized VDA module is adopted, the group efficiency is 65-70%, and the system energy density is 175Wh/ kg.At present, it has entered the second stage, using CTP technology, the group efficiency has reached 73-76%, and the system energy density has also increased to 185Wh/kg.Next year, Nezha Auto will launch the third-generation Tiangong battery system. Using CTP/CTC technology, the group efficiency can reach more than 85%, and the system energy density of the battery can also reach 210Wh/kg.At present, Nezha Auto has carried out pre-research on CTC technology and will cooperate with partners on this technology. At present, the prototype car has been finalized, which is very worth looking forward to.

Statement: the article only represents the views of the original author and does not represent the position of this website; If there is infringement or violation, you can directly feed back to this website, and we will modify or delete it.

Picture and textrecommendation

2022-06-02 11:57:10

2022-06-02 11:56:13

2022-06-02 11:55:28

Hot spotsranking

Wonderfularticles

2022-06-02 11:53:24

2022-06-02 11:52:48

2022-06-02 11:51:22

2022-06-02 11:50:50

2022-06-02 11:48:55

2022-06-02 11:43:54

Popularrecommendations