Your location:Home >Automotive News >

Time:2022-06-02 11:51:22Source:

In the blink of an eye, 2022 is nearly halfway through.Compared with last year, although the global chip shortage situation has been alleviated to a certain extent this year, it is still in a state of shortage in general, and there is still a period of time before it is fully alleviated.

Especially due to the continuation of the epidemic, geopolitical conflicts, etc., as well as the surge in demand fornew energy vehiclesin the end market , the industry generally believes that the lack of cores will continue to exist this year and next year or even in the longer term.Therefore, how to achieve a more stable chip supply and longer-term supply chain security is still an urgent issue for OEMs and Tier 1s to consider.

Under the influence of multiple factors, the lack of cores may become a protracted war

Image source: Screenshot of Shen Hui's Sina Weibo

On May 31, WM Motor CEO Shen Hui talked about his views on the recent Internet rumors that Bosch and other auto parts are brewing price increases. He said that Bosch and other Tier 1 price increases are not rumors, and this time. The "protagonist" of the price increase is still the chip."We made a simple estimate that the chip cost of smart electric vehicles has exceeded the battery pack. In this context, it is difficult for a single 10,000-yuan LiDAR to continue to heat up. This also means that the industry track of electric vehicles has shifted from batteries to batteries. Here comesthe chip."Shen Hui pointed out.

And just last week, the video of He Xiaopeng, chairman and CEO of Xiaopeng Motors, through the Internet celebrity "Da Da Duck" online "seeking core" was also popular on the Internet.In the video, "Da Duck" holding the words "Qi for Chip" online for help, which is funny and bitter.

Image source: Screenshot of He Xiaopeng's Sina Weibo

At a public event a few days ago, He Xiaopeng revealed the latest progress of this "seeking core".It is reported that after the release of the video, a friend helped to connect it soon. However, the chips that usually cost only a few yuan were quoted as high as 2,500-3,000 yuan, which is hundreds of times more. This result is really dumbfounding.

In fact, it has been more than a year since the auto industry was first exposed to a serious chip shortage at the end of 2020. However, at present, the lack of chips and the skyrocketing chip prices are still the top priorities for major car companies and parts companies.

According to the latest statistics from AFS, as of May 29, the globalproductionreduction of new cars due to core shortages has reached about 1.98 million this year, of which 794,600 vehicles have been reduced in the European market alone. largest area.From the perspective of price and delivery time, many overseas leaders have announced a new round of price increases this year. In addition, some dealers are hoarding goods, and the prices of some products have risen very ridiculously. The delivery time is still as long as 50 weeks. Rumors even Some companies are so lacking in cores that they have no choice but to dismantle the washing machine chips.

Based on in-depth research and judgment on the market, AFSpredictsthat the global auto market will reduce the production of 2.79 million new cars this year due to lack of cores. Although this result is significantly relieved compared to last year, it should be known that at the beginning of the year, AFS predicted that this year's new car production will be reduced by only 2.79 million new cars. 767,700 vehicles.This means that the core shortage problem currently faced by the automotive industry is much more severe than originally predicted.

"We started paying attention to chip makers in 2020, when we thought the chip supply problem could be alleviated by the end of 2021, and last year, we thought it could be alleviated in 2022. But now, we think the chip challenge will continue until this year or even next year. The time to come.” He Xiaopeng revealed at the second quarter financial report last week.It is conceivable that in the face of the core shortage crisis that has not been alleviated for a long time, there are not a few people who postpone expectations again and again.

There are many reasons behind this, and a large part of them are still related to epidemics, natural disasters and geopolitical conflicts.In addition to these uncontrollable factors, thesales of smart new energy vehiclescontinue to improve, which is further exacerbating the contradiction between supply and demand of automotive chips.According to previous statistics, from January to April this year, the cumulative production and sales of new energy vehicles in China reached 1.605 million and 1.556 million respectively, an increase of 1.1 times year-on-year, and the market share reached 20.2%, of which the production and sales in April were 312,000 respectively. and 299,000 units, a year-on-year increase of 43.9% and 44.6% respectively.This is still not included in the data of Shanghai, the market heat is evident.

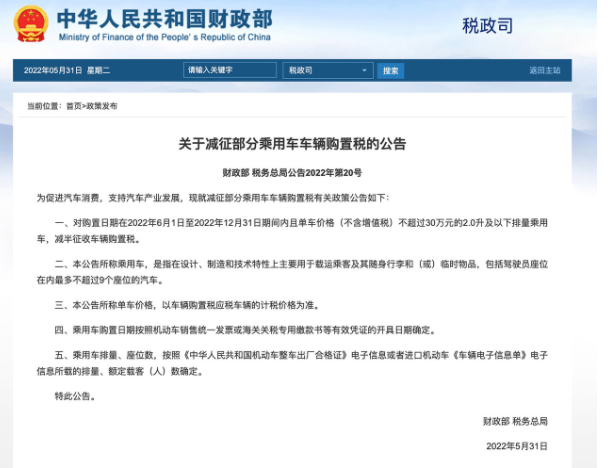

Next, as the Ministry of Industry and Information Technology, the Ministry ofAgriculture and Rural Affairsand other four departments have made it clear that a new round of new energy vehicles will be launched to the countryside, and at the same time, Shanghai, Shenzhen, Guangzhou and other places have introduced policies to stimulate vehicle sales, the new energy vehicle market is expected to continue to heat up.

The use of chips in smart new energy vehicles is far greater than that of traditional fuel vehicles.The industry generally believes that a fuel vehicle needs about 300-500 chips, while an intelligent new energy vehicle needs more than 2,000 chips. For a model with a relatively high level of intelligence such as Xiaopeng Motors, bicycle chips The amount has even reached 5,000, and the demand for chips will undoubtedly rise.

When Chen Yudong, President of Bosch China, responded that the pressure of the lack of cores has eased or increased compared to half a year ago, he said that the pressure has increased and that May was very difficult.He pointed out that due to various "black swan" events, the current chip supply has not returned to the situation before the chip crisis, and the supply is still in short supply.In addition, now all companies have increased their demand, especially the demand for chips for new energy vehicles is very large. A combination of factors has caused a continuous shortage of chips in the automotive industry.

Infineon Chief Marketing Officer Helmut Gassel recently revealed in an interview with the media that Infineon's backlog of orders from January to March 2022 has grown from 31 billion euros in the fourth quarter of last year to 37 billion euros, including unconfirmed orders. About three times its 2021 revenue, more than 50% of which are automotive-related products.In terms of delivery time, only 75% of these orders can be delivered within the next 12 months, which means that Infineon's backlog of orders has far exceeded its delivery capacity.

Also overloaded is ON Semiconductor.On May 10, it was reported that insiders of ON Semiconductor's Shenzhen plant revealed that all orders for its automotive IGBTs have been placed this year and next year, and now they are no longer accepting orders.

Intel CEO Pat Kissinger even said publicly that he had previously predicted a global chip shortage until 2023 and now expects it to last longer as chipmakers struggle to buy enough manufacturing equipment and ramp up production to meet the demand. meet demand.This means that the lack of cores is a protracted battle for the automotive industry.

"Core shortage"

Chips are widely used in automobiles, but not all categories are lacking.As He Xiaopeng said earlier, most of the most in short supply are cheap chips, not the very expensive chips that many people pay attention to to start a business.

But precisely this type of chip is a highly monopolized market.Taking the most serious shortage of automotive-grade MCUs as an example, the current global market is basically monopolized by international manufacturers such as Renesas Electronics, NXP, Infineon, and TI, with a market share of over 95% and a domestic market share of less than 5%. Typical "neck stuck" technique.

China is the world's largest automobile producer, and it is at the forefront of the world in the fields of automobile electrification and intelligence. The demand for automotive-grade MCUs is very extensive, and it is imperative to increase the domestic production rate.

To this end, in the past two years, many companies have begun to make efforts to deploy automotive-grade MCUs.Recently, the Hubei Province Vehicle-Grade Chip Industry Technology Innovation Consortium, led by Dongfeng Motor, was officially launched. One of the main directions of the consortium is vehicle-grade MCUs.Prior to this, the Hubei Provincial Department of Science and Technology had arranged a special fund of 10 million yuan last year to start a major science and technology project of "vehicle-grade MCU and special-purpose chips and controllers".

SAIC Group also clarified the localization strategy of large computing power chips and MCU chips last year, formed a list of 191 types of localized chips, and a list of 48 first batch of automotive electronic chip promotion projects, and promoted 75 chips to complete localization development. Enter the vehicle mass production application.

As early as the middle of last year, BYD Semiconductor, a subsidiary of BYD, achieved a vehicle-level MCU loading volume of over 10 million.In March this year, BYD Semiconductor further launched the car-grade 8-bit MCU BS9000AMXX series, which is mainly for the detection and control of body domain sensors, body domain end actuators, etc. At present, the client application development project has been launched.

The broad development space of domestic vehicle-grade MCUs has also attracted a number of traditional MCU companies and start-ups, including Xinwang Microelectronics, Chipsea Technology, Zhaoyi Innovation, Liyuan Information, National Core Technology, Jiefa Technology, Cloud A few of them have initially entered mass production, most of them are still in the design verification stage, and there is still a long way to go before mass commercialization. a certain distance.

In terms of application direction, in the fields of wipers, windows, taillight control, ambient light control, etc., domestic MCUs have initially achieved independent replacement, while in the motor drive control, body control, intelligent cockpit, new energy vehicle BMS and other core components and safety In related fields, the international manufacturers are still firmly in the dominance.

However, a positive signal is that under the background of chip shortages, more and more local companies have begun to consciously develop independent suppliers. Some self-owned brand car companies even have a certain proportion of the selection of automotive-grade chips. The domestic chip requirements allow domestic suppliers to take theopportunity to accelerate their introduction into the OEM supply chain and gradually increase their share.

Recently, SAIC Motor stated at the shareholders' meeting that under the current situation of repeated epidemics and unstable supply chains, various car companies are still sparing no effort to grab chips, strengthen resource reserves, and intensify efforts to promote the localization of automotive-grade chips. alternative.SAIC has also built a third-party joint evaluation platform for automotive electronic chips, aiming to reduce the repeated certification investment of chip companies and shorten the certification cycle.

Chen Yudong, President of Bosch China, also revealed that Bosch is currently actively supporting domestic chip companies, and Bosch will actively try domestic chips, and some of them are already in use."However, the high-end, key chips that affect ESP/EPS cannot be replaced in the short term because Bosch has participated in the design." Chen Yudong said.This also highlights that it is not easy for domestic MCUs to break through, especially in the field of high-end MCUs, there is still a long way to go to break through independently.

The challenges behind this are multi-faceted, not only because automotive-grade MCUs have strict testing and verification standards, as well as a long and complex certification cycle. Once the OEM confirms the supplier, it is difficult to easily replace the supplier. The key lies in the international manufacturers. Know-how accumulated through long-term support to OEMs.Even many large manufacturers have built special test methodologies, test lines and even customized processes, which are incomparable to local companies in the short term, not to mention that in terms of high-end processes and key materials, equipment, software, etc., domestic companies themselves are faced with relatively big constraints.

Perhaps from the perspective of application effects, the difference between some domestic MCUs and the products of international manufacturers is not large, but in fact, when OEMs and Tier1 choose a vehicle-grade MCU, in addition to product functions, in the mass production process. The stable quality, stable supply and cost of the product are also important considerations.In particular, once the automotive-grade chips are mass-produced, the supporting quantity will be tens of thousands or even hundreds of millions, which requires very high functional safety and reliability, and requires local players to be patient.

Statement: the article only represents the views of the original author and does not represent the position of this website; If there is infringement or violation, you can directly feed back to this website, and we will modify or delete it.

Picture and textrecommendation

2022-06-02 11:51:22

2022-06-02 11:50:50

2022-06-02 11:48:55

2022-06-02 11:43:54

2022-06-02 11:41:48

Hot spotsranking

Wonderfularticles

2022-06-01 13:19:43

2022-06-01 13:18:46

2022-06-01 13:15:15

2022-06-01 13:13:48

2022-06-01 13:12:55

Popularrecommendations