Your location:Home >Automotive News >

Time:2022-06-27 12:36:03Source:

A sudden epidemic reminds people of a fact that has been forgotten for a long time - the automobile industry was originally a complex and delicate industry.

The blockade in Shanghai caused NIO to stop production, and the blockade in Jilin caused FAW to cut off supply.The shutdown of urban socio-economic systems is a fatal blow to car companies.

Why?

It can be seen from public information that in 2021, theautomobile productionin the four regions of the Yangtze River Delta, Jiangsu, Zhejiang, Anhui and Shanghai will be 6.105 million vehicles, which together account for 23% of the country's total.In the top 100 Chinese auto parts companies in 2021 released by China Automotive News, a total of 38 companies in the Yangtze River Delta have entered the list.

Auto companies are not born to like to gather, but the industrial cluster effect can achieve low-cost and high-speed operation, which is the foundation of the automobile industry in the past century.

Urban clusters such as the Pearl River Delta and the Yangtze River Delta have attracted many car-making forces to choose the right layout by virtue of their perfect industrial chain.There are also companies that choose to deploy in both places. Those with strong assets and desperate attempts are like Evergrande Motors, which move forward cautiously and steadily, such as Hechuang Automobile.Compared with the former, which has delayed delivery indefinitely and has already rolled off the production line and delivered two products, Hechuang Auto seems to be more sincere towards the market and can go further.

Increased production capacity tospeed up development

Starting in 2021, the originally polarizednew energymarket has undergone some changes.With the maturity of the three electric technology, the acceptance of new energy products by fuel vehicle users is also increasing.Many fuel car owners consider replacing new energy models to cope with rising oil prices.

The transformation of consumer psychology has accelerated the transformation of the new energy vehicle market structure from "dumbbell type" to "spindle type", and 150,000-class trams have become a new competitive blue ocean market. Major car companies are eyeing this huge market group and show full sincerity Bring high-quality products to users, including BYD, Leapao, Nezha, Euler and other leading brands.

The Hengchi 5 of Evergrande Motor is rumored to be priced from 150,000, but it has not been delivered on a large scale, so it is not listed for the time being.Hechuang Automobile also has this level of products: the pure electric SUV model Hechuang Z03.The product was delivered on a large scale in November last year, and the annual model was officially launched in April this year according to user needs.

Compared with the top new energy brands, the configuration sincerity of the new model is not much better, and it has also received good market feedback.According to public information, after the launch of the Hechuang Z03, the cumulative orders exceeded 30,000, and the monthly sales exceeded 3,000 units in a row.However, there are also a series of problems such as the cold supply of chips and the shutdown of the supply chain caused by the epidemic in parallel with the hot market.The inability of production capacity to keep up with sales is a common pain point for new forces.

Looking at the new leading car-making forces, the production capacity layout has been placed in an important position.Leapmotor has built its own factory in Jinhua, Xiaopeng has built 3 factories in Guangzhou, Wuhan and other places, and NEO PAKR built in Hefei will have a vehicle production capacity of 1 million units per year.

What about the others?

A major foundation for the second echelon of the new forces to climb up is the revitalization of resources.In other words, whoever can maximize the input and output, has the hope of jumping from the middle to the bridge.

In January 2022, Hechuang Automobile became a shareholder of Guangcheng Hangzhou Company.This smart factory with an annual production capacity of 200,000 vehicles is undoubtedly an advanced springboard for Hechuang.

In order to meet the production needs of intelligent network-connectednew energy vehicles, Hechuang Automobile and Guangcheng Hangzhou have carried out system-wide optimization of production lines, focusing on the four dimensions of "production automation, information digitization, intelligent management, and intelligent manufacturing ecology".

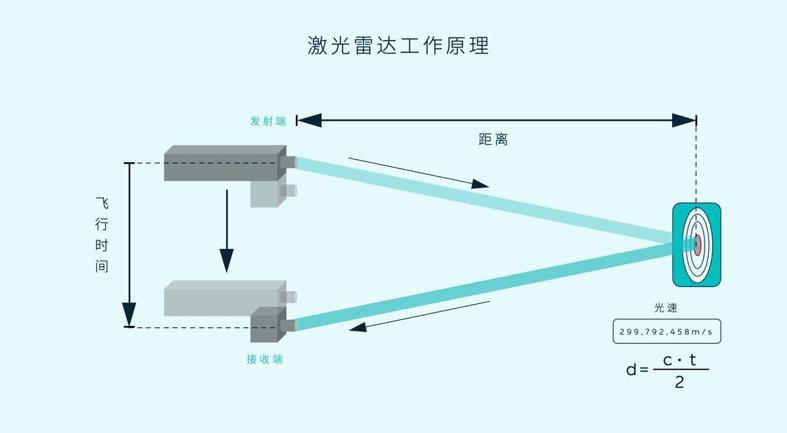

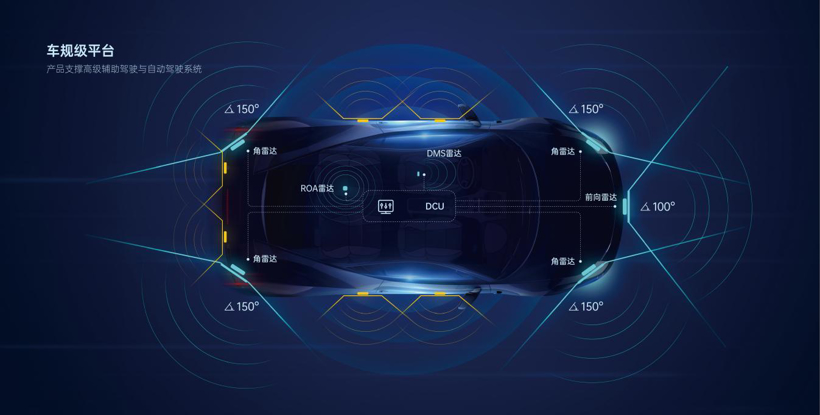

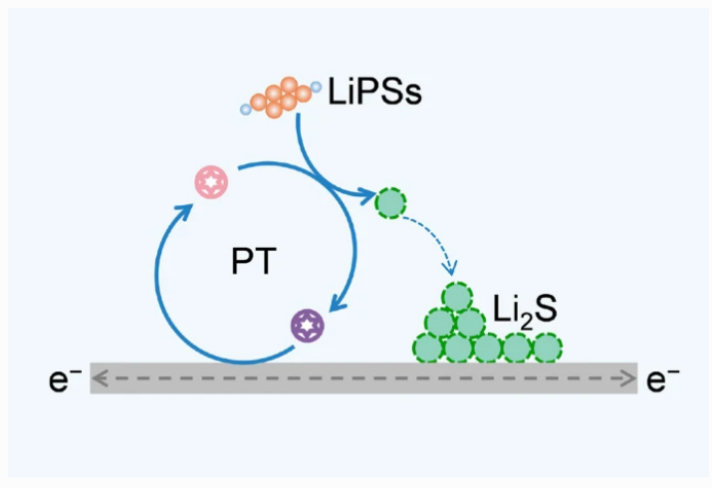

Such as the modification and upgrade of the chassis positioning mechanism, and the addition of battery delivery and automatic installation systems.In addition, according to the characteristics of new energyintelligent networkedvehicles, the quality inspection workshop of the whole vehicle is optimized. In its intelligent connected detection system, high-precision CCD laser imaging, ultrasonic sensor ranging and other technologies are used, which can detect vehicle cameras, radar and other technologies. Sensors, etc. for detection and calibration.Advanced process equipment and management methods enable Hechuang to continuously bring excellent product quality to users.

Sufficient production capacity, on the one hand, meets the strong delivery demand of the models on sale, and on the other hand, provides a solid guarantee for the new products that will be launched soon.Hechuang Automobile once said that it will face the new energy market with the rhythm of a new car every year.According to the plan, a pure electric coupe will be released this year, and there will be MPV and other models in the future.

Deploying production in the two places is an excellent choice for Hechuang to break through the bottleneck of its own production capacity and speed up the product process.

Collaborative supply to ensure a solid foundation

Boosting production capacity determines how far an enterprise can go, and the supply chain determines whether an enterprise can go to tomorrow.

"Da Duck is easy to buy, but chips are hard to find."

Although He Xiaopeng's Weibo was funny, it also revealed a little helplessness.The supply chain cannot be built in a day, and even a leading new force like Xiaopeng cannot escape the constraints.

How important is the supply chain to car companies?

Originally, car manufacturers were called OEMs or OEMs, because they only mastered core technology and assembly, and the rest of the links were highly divided.A new energy vehicle has at least more than 1,000 parts from more than 200 suppliers.If any one of them loses the chain, the assembly progress of the whole vehicle will be affected.

This is the second major advantage of industrial clusters.The more suppliers gathered around a car company, the shorter the supply cycle and the smaller the supply chain risk.

Therefore, another profound meaning of Hechuang's layout in Hangzhou has surfaced.

As a traditional manufacturing province in the automotive industry chain, Hangzhou, Ningbo, Taizhou and other industrial clusters have obvious advantages, including the chips and components required for the three-electric system, body system, and electronic and electrical architecture required for new energy vehicles. Domestic suppliers can provide support.Expanding to the entire Yangtze River Delta region, there are more than 600 auto parts companies above designated size.

There are also inclinations in policy.In July last year, the "14th Five-Year Plan for the Development of Hangzhou's Energy-Saving and New Energy Vehicle Industry" proposed that by 2025, the energy-saving and new energy vehicle industry should be developed into a leading industry that promotes the high-quality development of Hangzhou.Among them, the production of new energy vehicles will be 313,000 in 2025, and 6,000 public and shared charging piles will be added, and more than 100,000 new energy vehicles will be promoted and applied.

Hechuang chooses Hangzhou, on the one hand, enjoys the policy of "free shipping area" and the advantages of supply chain; Even, the distance with the vast market of the Yangtze River Delta has narrowed.

Since last year, Hechuang has made frequent actions on the road of independent research and development, including the establishment of a joint research and development center for intelligent connected vehicles with Shanghai Jiaotong University, and strategic cooperation with leading companies in the upstream and downstream of the industry chain such as Bosch, Horizon, and Shanghai Zhijia.With the relocation of Hechuang Automobile to Hangzhou, the production capacity has been improved and the supply chain has been gradually improved.All of this implies that Hechuang Automobile is rushing on the road of integration of research, production and sales.

Epilogue

The landing of Hechuang Z03 in Guangcheng Hangzhou factory is a leap for Hechuang to break through the bottleneck of production capacity and lay out the industrial chain. It may be difficult to see results in a short period of time, but it is an important milestone for Hechuang's development. .

Today's China's new energy vehicle track, strong players are like forests.Hechuang needs to further accelerate the integration of research, production and sales, and strengthen the moat, so that it can win the battle.

Statement: the article only represents the views of the original author and does not represent the position of this website; If there is infringement or violation, you can directly feed back to this website, and we will modify or delete it.

Preferredproduct

Picture and textrecommendation

2022-06-27 12:27:05

Hot spotsranking

Wonderfularticles

2022-06-24 22:03:08

2022-06-24 22:03:04

2022-06-24 22:02:14

Popularrecommendations