Your location:Home >Automotive News >

Time:2022-06-09 11:14:36Source:

As we all know, power battery is the most important part of the three-electric system ofnew energy vehicles, and its cost accounts for 40% of the cost of the whole vehicle.Therefore, reducing battery costs has always been one of the important tasks of battery suppliers and OEMs.Among them, the integration of batteries has always been a breakthrough point in research and development. Following CTP technology, CTC and CTB technologies have triggered a new wave of new technologies sweeping the pure electric field.For example, BYD recently released the CTB battery body integration technology and Leaprun's battery-free CTC technology.

So what are the respective principles of these different battery integration technologies, and what are the advantages and disadvantages?Let's take a look at those things about batteries.

From CTP to CTC/CTB

At first, the traditional car batteries were packaged into modules by cells, and then the modules were installed in the battery pack to form a three-level assembly mode of "cell-module-battery pack", that is, CTM technology (Cell to Module). ).Such a design can reduce heat transfer between modules in the event of an accident or failure.However, this packaging method has a large number of parts and requires many cables and structural parts, resulting in low space utilization.

With the gradual maturity of safety technology and the improvement of CTM, the second generation of vehicle battery - CTP (Cell to Pack) came into being.Compared with CTM, CTP skips the link of standardized modules and directly uses cells to form battery packs, so its space utilization and energy density are improved.

For example, Tesla Model 3 and Xiaopeng P7 on the market have applied CTP technology.At the same time, it is worth mentioning that the blade battery released by BYD in 2020 is also a CTP technology. Different from the above method, BYD's CTP technology focuses more on the "C" (ie, the battery cell), arranging the battery cells. Together, inserted into the battery pack like a blade, its volume usage has been increased to more than 50%.This is also the reason why although it is a lithium iron phosphate battery, it does not lose the ternary lithium battery in terms of battery life.

To sum up, CTP technology has achieved the simplification of battery integration, but can the battery pack also be removed?

With the increasing requirements of various car companies for portability andlight weight, CTC and CTB technologies have emerged.Referring to the above figure, compared with CTP technology, the most notable feature of these two technologies is the cancellation of the application of battery packs.But in essence CTC and CTB belong to two technical branches.

Among them, the concept of CTC was first proposed by Tesla. On the Tesla Battery Day in 2020, Musk explained the CTC technology with the image of the wing, “Originally, the aircraft will place the fuel tank in the wing, but In order to use the space to a greater extent, the fuel tank was removed and the fuel was stored directly in the wings, so that more fuel could be accommodated.”

In this way, Tesla connects the top cover of the battery pack and the battery cells and integrates them with vehicle structural parts such as seats.Compared with CTP's battery integration method, CTC directly reduces 370 parts, while the vehicle weight is reduced by 10%, but the mileage is increased by 14%.

In April of this year, Leapmotor also released the CTC battery-chassis integration technology, and took the lead in mass production and application on Leapmotor C01, an electric medium and large car on the Leapmotor C platform.According to the official data of Leaprun, the Leaprun CTC solution cancels the battery pack box and upper cover, leaving the integrated cell module and battery lower tray.Strictly speaking, Tesla is more in line with the requirements of CTC. The CTC of Leaprun still has a battery module, the chassis is under the seat, and the battery is under the chassis. To put it bluntly, the chassis is just thinner. .

Cao Li, vice president of Leapmotor Technology, also said that the difficulty of CTC technology is not in materials or processes, but in the cooperation of forward joint development, which requires teams of body, chassis and battery to develop together.From this point of view, it may take more time for Leaprun to perfect its CTC technology.

Let's learn about CTB technology. In short, the concepts of CTC and CTB are similar. They both integrate the chassis and the body. The difference is that the CTB retains the original reinforced beam structure of the body.

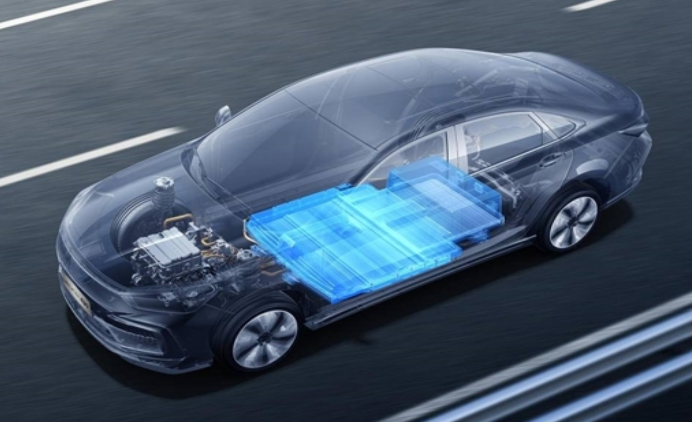

Take the BYD seal equipped with CTB as an example. It just takes out the floor on the frame, uses the upper cover of the battery pack as the floor, and steps on the battery pack cover.The battery cell uses a blade battery that is different from the ternary lithium battery, and forms a state of direct battery connection.This not only improves the driving experience of the vehicle, but also enhances the safety of the whole vehicle.

Three technologies, which one to choose?

Nowadays, the automobile industry can be said to have ushered in a major change unseen in a century. Major car companies have deployed and launched an "arms race" in the field ofnew energy, using technology to brighten tomorrow's glory.

At present, most OEMs still use CTP technology in battery integration at this stage, mainly because R&D is a long process that requires high investment and high energy, and most manufacturers do not have such strong technical R&D capabilities.Therefore, although CTC and CTB technologies are the future trends, only Leapmotor, BYD and Tesla are currently using them. Other car companies have chosen CATL to supply batteries.

In addition, the battery swap technology of CTP is relatively mature, and the problem of charging and energy supplementation has always been a problem that plagues electric vehicle users.In the current situation where CTC and CTB technologies are not yet perfect, policies and the market promote power exchange to become an important part of the energy supplement system, such as the rechargeable, exchangeable and upgradeable energy system that NIO has gradually established.According to data from the China Charging Alliance, as of April 2022, the number of domestic battery swap stations has reached 1,480, forming a certain scale.This situation makes CTP, CTC, CTB maintain the state of coexistence in the short term.

But in the long run, CTC and CTB will definitely be the mainstream technologies in the future with higher space utilization and longer battery life.It's just that most car companies currently have limited technical support for the three-electric system and car manufacturing process, but I believe this is only a matter of time.

Then CTC and CTB technology, who can have the last laugh and lead the future?

From the perspective of integration, the battery cover of CTC technology directly acts as the lateral beam and interior floor of the body, and the side beam acts as the chassis structure.The CTB technology retains the lateral frame and chassis longitudinal beam of the body, so the CTC has a higher degree of integration.

But at the same time, the overall strength of CTC is not as good as that of CTB because of the abandonment of the body beam, and the blade battery used by CTB has more reliable safety than the ternary lithium battery of CTC, which makes the torsional strength of the body equipped with CTB technology far exceeds that of CTC. The body strength has reached an astonishing 40,000N m.

And in terms of maintenance costs, generally the higher the degree of integration of the battery pack, the higher the maintenance costs.Taking Tesla's CTC technology as a reference, its battery not only acts as part of the chassis structure, but also connects to the floor, seat and slide rails in the car body part, making it difficult to repair in the event of an accident.The CTB battery can be easily disassembled as an independent module.Considering the current technical level, CTB's requirements for connection process and welding process are not as high as CTC's. Therefore, CTB has greater advantages after comprehensive consideration.

write at the end

In general, whether it is CTB or CTC, it can improve the battery life of the vehicle to a certain extent, but the development of integrated technology is still a long way to go. This needs to be solved by breaking the bottleneck of electric vehicle energy replenishment and battery life. Consumer pain points to achieve.

At the same time, we need more car companies like BYD to take the initiative in the changing times. Even if CTB will not become mainstream in the future, we also have exclusive technology and a complete supply chain. emboldened.Only in this way, our own brand will truly achieve overtaking on the international track.

Statement: the article only represents the views of the original author and does not represent the position of this website; If there is infringement or violation, you can directly feed back to this website, and we will modify or delete it.

Preferredproduct

Picture and textrecommendation

2022-06-09 11:32:20

2022-06-09 11:30:16

Hot spotsranking

Wonderfularticles

2022-06-09 11:29:41

2022-06-09 11:25:08

2022-06-09 11:22:08

Popularrecommendations