Your location:Home >Automotive News >

Time:2022-07-13 14:59:22Source:

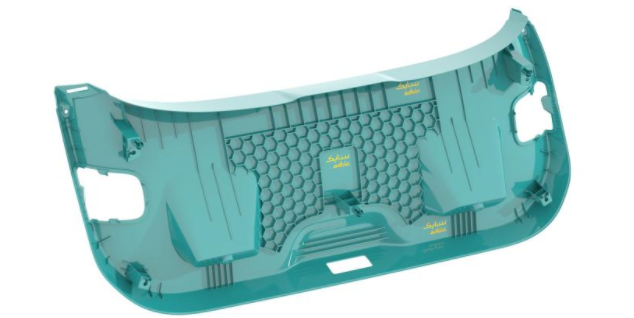

Gasgoo News According to foreign media reports, Saudi Arabia Basic Industries Corporation (Sabic Industries, Sabic) has launched a dedicated Sabic PP compound product portfolio for foam injection molding (FIM), namely new mineral-enhanced PPc F9005, PPc F9007 and PPc F9015 grade helps achieve an aesthetic appearance for visible automotive interior components with complex geometries such as door panels and trim, seat and trunk cladding, A/B/C/D pillar covers and center consoles.

Image credit: Shakey

Unlike standard FIM materials that typically exhibit surface defects, this new advanced PP compound has a uniform high surface quality similar to solid injection molded parts.Foamed parts made with sand-based PP compounds offer significant weight savings compared to solid parts, helping to reduce emissions.According to a life cycle assessment study (pending third-party review), the advanced material can help OEMs reduce carbon dioxide (CO2) emissions by up to 15 percent.

Previously, the FIM process was largely limited to non-visible parts, limiting its usefulness in automotive applications.Foams may not perform well in terms of surface aesthetics, as silver streaks, swirls and dents are very common.But sand-based PP compounds for foam upholstery provide a low-gloss textured (grainy) surface with consistent high quality and eliminate streaks and swirls.These talc fillers act as nucleating agents, promoting finer air bubbles to help maintain a consistent surface appearance.To enhance the aesthetics, these compounds also enable more color options for car interiors, which of course can be customized.

The weight loss effects of sandy PP compounds depend on several factors, including the type of FIM technique used.Short shot molding uses the same tooling as injection molded parts and can save up to 10% in weight.Sandy PPc 9007 is formulated for short shot FIM and low impact applications.

Core back molding, which requires redesigned parts and new tooling, can reduce weight by up to 30 percent.Sandky PPc 9005 and PPc 9015 grades are both formulated for core backing and provide medium stiffness and impact.

Short-shot and re-core techniques can be selected for different tool requirements, helping to determine whether FIM using sand-based PP compounds can reduce costs.Further cost savings can be achieved by shortening cycle times through the flow improvements inherent in FIM.

Another consideration is the foaming process, which can use chemical or physical agents.The new sand-based PP compounds are ideal for use with chemical blowing agents, which are often the first choice for visible foam parts.These agents are introduced into the molding machine in the form of a masterbatch together with the plastic pellets and activated during the melting stage to release gas for foaming.

Shaky 's extensive expertisein foam part design, development and processing, as well aspredictive engineering, fully supports its new portfolio of PP compounds.For example, the company can provide guidance on the selection of the appropriate chemical blowing agent for each grade.The Shakey technical team will work with the customer to achieve the desired aesthetic with the lowest possible part weight.

Statement: the article only represents the views of the original author and does not represent the position of this website; If there is infringement or violation, you can directly feed back to this website, and we will modify or delete it.

Preferredproduct

Picture and textrecommendation

2022-08-04 12:57:12

2022-08-04 12:56:48

2022-08-04 12:56:28

2022-08-04 12:56:04

2022-08-04 12:55:36

2022-08-04 12:55:11

Hot spotsranking

Wonderfularticles

2022-08-04 12:54:48

2022-08-04 12:54:20

2022-08-04 12:53:54

2022-08-04 12:53:32

2022-08-04 12:53:03

2022-08-04 12:52:26

Popularrecommendations