Your location:Home >Automotive News >

Time:2022-07-11 11:48:18Source:

Gasgoo NewsLightweightis a major trend in the automotive industry today, including battery housings.According to foreign media reports, at present, some companies are racing to develop related business solutions.

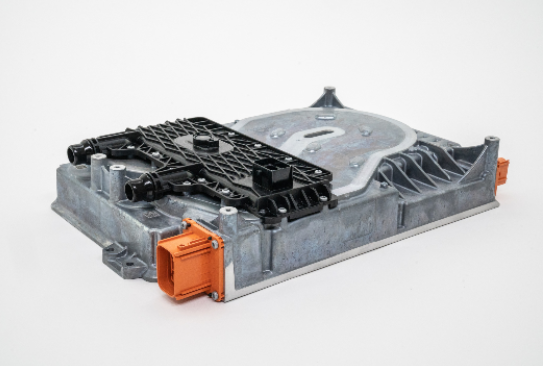

(Image source: LANXESS)

For example, German specialty chemicals company Lanxess and auto parts supplier Kautex Textron are targeting direct long-fiber thermoplastics (D-LFT) and polyamide 6 (PA 6) resins Conduct a feasibility study.Meanwhile, the Spanish Institute of Plastics Technology (Aimplas) is developing sustainable structural battery housings for light-duty vehicles using reusable, recyclable long-fiber thermoplastic composites, making discharged battery packs hot-swappable.Elsewhere, the Vestaro Alliance is taking a novel approach to using lightweight sheet molding compound for high-voltage battery module housings.

Shift to PA 6

At present, a series of progress has also been made in the secondary battery components ofelectric vehicles, of which LANXESS is once again at the forefront.According to the nylon supplier, PA 6 and PA 66 have very similar properties and are often in competition with each other.Recently, the price of PA 66 is tight, and the supply is temporarily limited, which makes it easy to be replaced by PA 6 in traditional applications.Components manufactured in PA 66 are usually used in new developments, and now PA 6 is being used directly.

One current use case is a cover for a car charger.The charger is used in a compact electric vehicle produced by a German automaker.The cover uses LANXESS' Durethan BKV50H3.0, which contains 50% short glass reinforcement.Germany's Leopold Kostal GmbH & Co. KG makes the system, including the cover and charger.It is a global system supplier of automotive, industrial and solar electrical and electrical connector systems.

This large-scale application underscores the fact that PA 6 does not necessarily have to be hydrolytically stabilized for use in cooling units with glycol-water coolants in electric vehicles.

Dr. Bernhard Helbich, Technical Key Account Manager at LANXESS Performance Materials, said: "In the future this polyamide 6 product is likely to become increasingly popular for the mass production of covers and other thermal management components in electric vehicles, especially in cooling systems. fluid connectors or control unit applications.”

Electric drive systems have different thermal management requirements

Plastic components in the cooling circuit of internal combustion engines have always been dominated by PA 66.Because this thermoplastic is highly resistant to thermal coolants such as water glycol mixtures.However, the thermal management requirements of pure electric powertrains are shifting to lower temperatures.In pure electric vehicles, the long-term thermal resistance of polyamide 6 compounds to water-glycol mixtures is sufficient for most components, even in some cases for longer stress periods.This cover from LANXESS can therefore withstand temperatures of up to 85°C for long periods of time during vehicle operation and with burst loads of up to 10 ba.Long-term testing of the samples also showed that the mechanical properties of the compound in a water-ethylene glycol mixture showed little degradation even after 1500 hours of storage at 110°C and a pressure of 1.5 bar.The material thus meets the technical requirements of the major German automaker for water-cooled components for electric vehicles.

This cover is about 29 cm long and 12 cm wide, with a fairly long flange length.Thread the cover along with the seal onto the aluminum housing of the charger.The high strength and stiffness of the PA 6 compound ensures that the lid can meet stringent tightness requirements."By working closely with Kostal, optimizing mechanical component performance, and performing simulated filling, it was possible to determine how to minimize shrinkage and warpage during injection molding," Helbich said.

In addition, Durethan BKV50H3.0 uses a copper-free H3.0 heat stabilizer that does not cause electrical corrosion of metal parts in the cooling circuit.The material is resistant to media commonly used in electric vehicle operation, such as motor oil, grease, battery electrolyte, and deicing salts.

Statement: the article only represents the views of the original author and does not represent the position of this website; If there is infringement or violation, you can directly feed back to this website, and we will modify or delete it.

Preferredproduct

Picture and textrecommendation

2022-08-04 12:57:12

2022-08-04 12:56:48

2022-08-04 12:56:28

2022-08-04 12:56:04

2022-08-04 12:55:36

2022-08-04 12:55:11

Hot spotsranking

Wonderfularticles

2022-08-04 12:54:48

2022-08-04 12:54:20

2022-08-04 12:53:54

2022-08-04 12:53:32

2022-08-04 12:53:03

2022-08-04 12:52:26

Popularrecommendations