Your location:Home >Automotive News >

Time:2022-07-11 11:47:46Source:

In a paper published in ACS Energy Letters, researchers discuss a new single-step method for electrochemical lithium extraction,media reported.In contrast, previously commonly used separation/purification steps tend to increase costs.

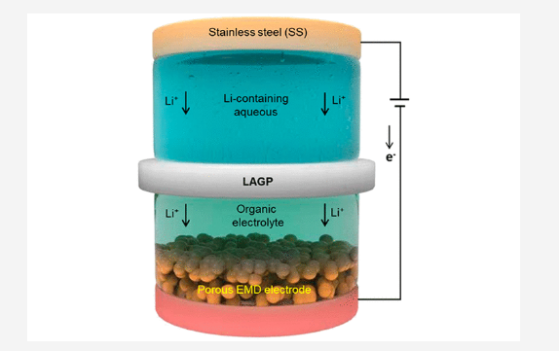

(Image credit: ACS)

With the rapid development ofelectric vehicles, the demand for lithium batteries is also growing.Therefore, lithium becomes a very important commodity.Demand for lithium is expected to exceed 2 million tonnes by 2030.Now, people take the method of separating and purifying lithium from ore.However, the limited and inconsistent global distribution of lithium often fails to meet demand; secondly, deposition and purification processes are slow and inefficient (50% recovery).Standard centrifugation techniques, which require pre-concentration of brine, sedimentation reagents and separation of lithium, are time-consuming and expensive, despite some technical capabilities.

Novel lithium extraction method

There is a unique method of electrodialysis that uses a homogeneous lithium nanocomposite to extract lithium with a recovery of over 7% after 72 hours.Furthermore, in this study, the researchers created and validated an electrochemical technique utilizing solid Li1+xAlyGe2-yPO43 thin films to adsorb lithium metal from simulated seawater.

However, the compositional change and persistence of lithium compounds in aqueous solutions are key to continuous lithium processing technologies.After lithium extraction, extensive and costly absorbent replacement and lithium filtration processes are still required to produce usable lithium on an industrial scale.This is a common challenge faced by the above-mentioned lithium extraction processes.

This innovative technology is slightly different in a few ways.Based on a combination of membrane electrolysis and electrochemical intercalation processes, a lithium-ion-specific barrier (Li1.5Al0.5Ge1.5(PO4)3, LAGP) and low-cost electrochemical manganese dioxide (EMD) were used as the barrier and lithium host, respectively .The researchers focused on materials with superior lithium separation performance and efficiency, and control of subsequent processing costs, without using low-capacity compounds such as FePO4, which is inherently reconfigurable.

Advantages of modern technology

The new technique proposed by the researchers has three main advantages.First, the extracted lithium is very pure; second and most importantly, there is no need to spend a lot of money for lithium separation and purification; the third advantage is high efficiency and low cost.

According to the expected cathode formulation, the collected Li and electrolytic manganese dioxide host (Li-EMD) become the preliminary components of the cathode for rechargeable batteries, which can be efficiently used to synthesize cathodes with necessary components.

The study found

Based on the measured lithium removal ability and the expected EMD potential, the total lithium intercalation volume was 220 mAHg-1, or the recovery efficiency was 71.4%.If all manganese ions are considered to be 4+ valent, the reported collection capacity suggests that 0.772 moles of lithium can be extracted using 1 mole of EMD, which is consistent with chemical analysis.

In the Techno-Economic Analysis (TEA), the cost of producing a lithium battery cathode is calculated using lithium extracted through the EMD/LAGP process.The results show that the cost of producing spinel LiMn2O4 and NMC333 using this technology is lower than that of other lithium separation technologies, and even equal to the cost of consumer applications.

In a nutshell, this method of lithium extraction helps to address the low availability of lithium and the cost of batteries, thereby enabling vehicleelectrificationand reducing emissions from socio-economic systems.

Statement: the article only represents the views of the original author and does not represent the position of this website; If there is infringement or violation, you can directly feed back to this website, and we will modify or delete it.

Preferredproduct

Picture and textrecommendation

2022-08-04 12:57:12

2022-08-04 12:56:48

2022-08-04 12:56:28

2022-08-04 12:56:04

2022-08-04 12:55:36

2022-08-04 12:55:11

Hot spotsranking

Wonderfularticles

2022-08-04 12:54:48

2022-08-04 12:54:20

2022-08-04 12:53:54

2022-08-04 12:53:32

2022-08-04 12:53:03

2022-08-04 12:52:26

Popularrecommendations