Your location:Home >Automotive News >

Time:2022-07-08 12:26:03Source:

According to foreign media reports, Toray Industries, Inc. of Japan announced the manufacture of an ion-conducting polymer film that can be used in lithium-air batteries.The film can be used as a battery separator, helping to improve the safety and longevity of batteries and extend the range ofelectric vehicles.

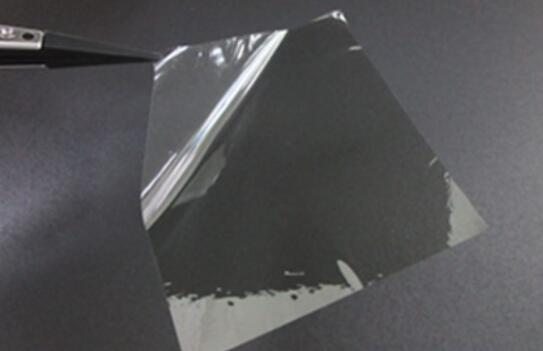

(Image source: Toray Corporation)

With the rapid development of electric vehicles, the demand for rechargeable batteries is also surging.These batteries must be lighter and provide higher energy density to increase the range of electric vehicles.

Compared with traditional lithium-ion batteries, lithium-air batteries are lighter and have a theoretical specific energy density of 10 times.Microporous separators are commonly used in such batteries.The disadvantage of using a microporous membrane is that after repeated charge-discharge cycles, the different electrolytes used in the positive and negative electrodes will be mixed together; another problem is that the lithium dendrites formed during the charging process may pierce the separator, resulting in positive and negative Short circuit between electrodes.These will affect the safety of the battery.

To solve these problems, Toray has designed a polymer that can realize lithium ion hopping (referring to the transition of lithium ions between adjacent sites during conduction), and used high heat-resistant aramid polymer molecular design technology to manufacture Lithium salt compound.As a result, a non-porous polymer film having an ionic conductivity of 3 x 10-5 S/cm was obtained.This high conductivity enables the battery to work without the film being porous.In principle, this lack of porosity enables two types of electrolyte separation and suppresses lithium dendrite formation.

Toray has confirmed that lithium metal batteries using its ion-conducting polymer film have stable operation times in charge-discharge cycles that are 10 times longer than those using microporous films.The company said it would speed up research and development to use the new technology in rechargeable batteries, including lithium metal batteries.

Statement: the article only represents the views of the original author and does not represent the position of this website; If there is infringement or violation, you can directly feed back to this website, and we will modify or delete it.

Preferredproduct

Picture and textrecommendation

2022-08-04 12:57:12

2022-08-04 12:56:48

2022-08-04 12:56:28

2022-08-04 12:56:04

2022-08-04 12:55:36

2022-08-04 12:55:11

Hot spotsranking

Wonderfularticles

2022-08-04 12:54:48

2022-08-04 12:54:20

2022-08-04 12:53:54

2022-08-04 12:53:32

2022-08-04 12:53:03

2022-08-04 12:52:26

Popularrecommendations